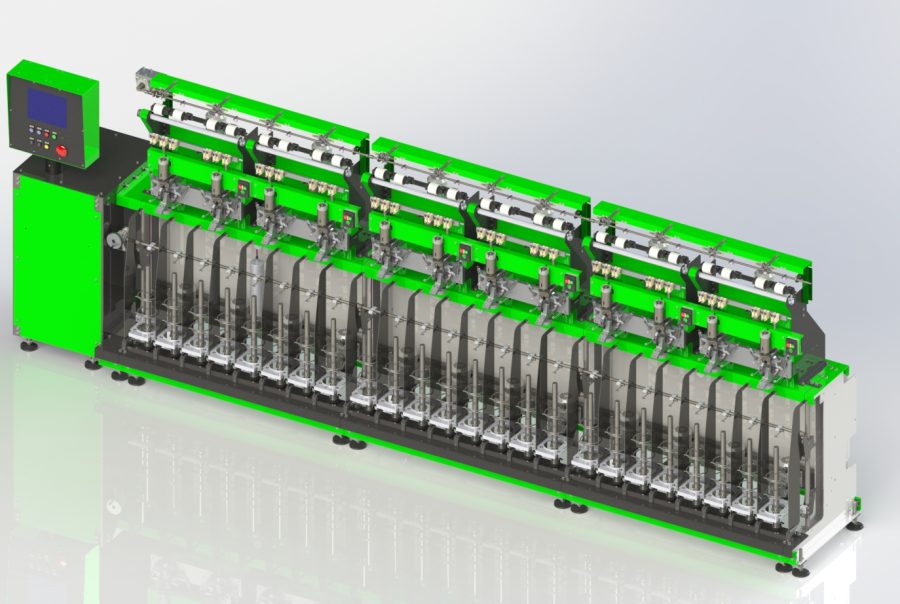

New chenille forming group aimed at better cutting accuracy as well as longer gauge life.

Each head group is independent and capable of producing a chenille different from each other.

New chenille forming group aimed at better cutting accuracy as well as longer gauge life.

Each head group is independent and capable of producing a chenille different from each other.

Chenille machines next-step.

Fully electronic Full-Drive machine.

Usage of chenille for:

Through PC Touch Screen you can enter and save all the work data and technical parameters of the final yarn and control the machine’s functionalities.

The PLC manages the precise execution of the data, ensuring the exact speed of the axes in a millesimal measure with exceptional results on the quality of the effects of the final product. Extremely easy to enter and edit general data in a step-by-step or quick mode. Diagnostics for the detection of the state of the machine.

TECHNICAL DATA

Gauge [mm]

150 mm

Ring diameter [mm]

115 mm

Spindles/section

8

Max No. spindles

120 (consigliati)

Max spindles speed [rpm]

8.500 rpm

Max needle head speed [rpm]

18.000 rpm

Max production speed [m/min]

18 m/min

Collection: ring tube [mm]

450 mm

Installed power [Kw]

40 Kw

Absorbed power

50-60%